Description

Embedment RTD sensors are most commonly used to monitor the bearing temperatures of rotating equipment. The recognition of a rising temperature can provide an early warning of the breakdown of the lubrication. This early warning allows the process to be shut-down for maintenance before a major breakdown or costly failure occurs.

The miniature bearing sensors provide a cost-effective solution to bearing temperature monitoring.

Suitable for use between -25°C and +260°C.

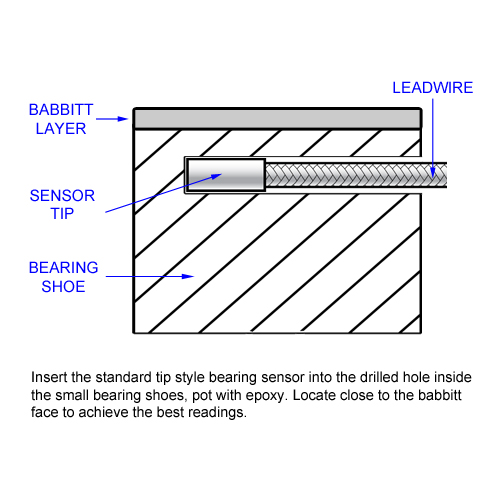

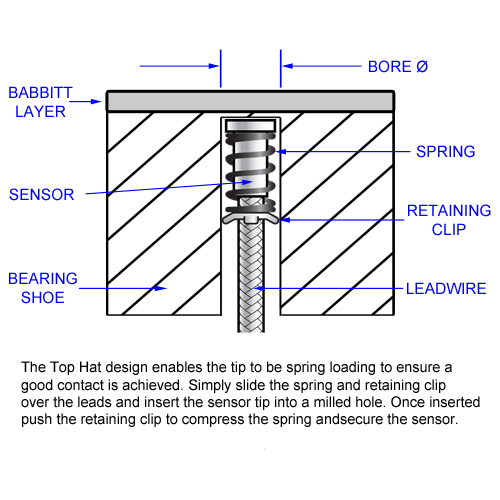

Easy to install, the sensors are inserted directly into the bearing shoes, in or beneath the Babbitt layer. The small diameter tips are commonly epoxy sealed into drilled holes in the shoes, whilst the spring loaded style tip is inserted into a milled hole, the self-locking retaining clip is then pushed into the hole to compress the spring.

The D (Top-Hat) Style Tip is supplied with a retaining clip and spring.

This product can be supplied with a calibration certificate.

Bespoke Options

This product can be custom-made and/or configured to your requirements using the options below. Each option has a code that is used to construct a final order code. An example order code is included.

Sensor Type

| Sensor Type |

Code |

| Miniature Embedment/Bearing RTD (Pt100) Sensor |

PPB |

Detector Elements

| Detector Elements |

Code |

| Simplex (1 channel) |

S |

| Duplex (2 channels) |

D |

Wiring Configuration

| Wiring Configuration |

Code |

| 2-wire |

2 |

| 3-wire |

3 |

| 4-wire (Simplex only) |

4 |

Grade of Element

| Grade of Element |

Code |

| B (± 0.30°C @ 0°C) (± 0.80°C @ 100°C) |

B |

| A (± 0.15°C @ 0°C) (± 0.35°C @ 100°C) |

A |

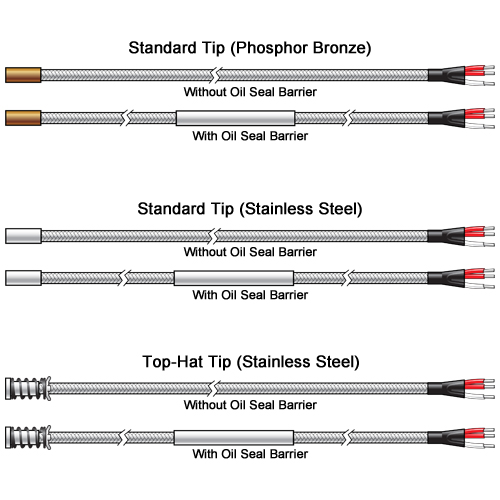

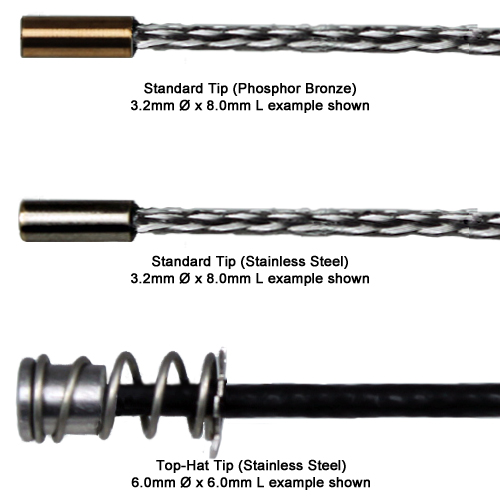

Tip Style & Dimensions

| Standard Tip |

Code |

|

Top-Hat Tip |

Code |

| Tip Diameter (D1) |

Tip Length (L1) |

Phosphor Bronze

|

Stainless Steel

|

|

Tip Diameter (D1) |

Tip Length (L1) |

Stainless Steel

|

| 3.0mm |

8.0mm |

- |

ZS |

|

6.0mm |

6.0mm |

THC |

| 3.2mm (1/8") |

8.0mm |

AP |

AS |

|

6.35mm |

6.0mm |

THD |

| 4.0mm |

9.0mm |

BP |

BS |

|

Top-Hat Tip Accessories |

| 6.0mm |

6.0mm |

CP |

CS |

|

RC846 Retaining Clip

8mm OD x 4mm ID, 6 prongs |

| 6.35mm (1/4") |

8.0mm |

- |

DS |

|

RS126 Spring

12mm x 6mm dia. |

Extension Cable

| Extension Cable Length (L2) |

Cable Construction |

3-wire Code |

4-wire Code |

6-wire Code |

8-wire Code |

| (simplex 3-wire) |

(simplex 4-wire) |

(duplex 3-wire) |

(duplex 4-wire) |

As required to suit your application

(e.g. 1000mm) |

7/0.15mm conductors, extruded PFA, Twisted, PFA overall |

PT4315 |

PT4415 |

PT4615 |

PT4815 |

| 7/0.15mm conductors, extruded PFA, Twisted, Stainless Steel Wire Braided overall |

PT3315/SSB |

PT3415/SSB |

PT3615/SSB |

PT3815/SSB |

| 7/0.10mm conductors, extruded PFA, Twisted, Stainless Steel Wire Braided, PFA overall |

PT6310 |

PT6410 |

PT6610 |

- |

| 7/0.10mm conductors, extruded PFA, Twisted, Stainless Steel Wire Braided overall |

- |

- |

PT3610/SSB |

- |

Optional Oil Seal Barrier *

| Diameter (mm) (D2) |

Std Length (mm) (L3) |

Code |

| 3.0 |

60.0 |

OSB Diameter x Std Length

(e.g. OSB 6.0 x 60.0) |

| 3.2 (1/8") |

60.0 |

| 4.76 (3/16") |

60.0 |

| 5.5 |

60.0 |

| 6.0 |

60.0 |

| 6.35 (1/4") |

60.0 |

* Tested to a minimum pressure of 5 bar for a minimum of 30 minutes

Extension Cable Compatibility (prefix code with required length L4 e.g. 1000mm PT4315)

| Simplex 3-wire |

Simplex 4-wire |

Duplex 3-wire |

Duplex 4-wire |

| PT4315, PT3315/SSB |

PT4415, PT4415/SSB |

- |

- |

| PT4315, PT3315/SSB |

PT4415, PT4415/SSB |

- |

- |

| PT4315, PT3315/SSB, PT6315 |

PT4415, PT3415/SSB, PT6415 |

PT3610/SSB |

- |

| PT4315, PT3315/SSB, PT6315 |

PT4415, PT3415/SSB, PT6415 |

PT4615, PT3615/SSB, PT6615, PT3610/SSB |

- |

| PT4315, PT3315/SSB, PT6315 |

PT4415, PT3415/SSB, PT6415 |

PT4615, PT3615/SSB, PT6615, PT3610/SSB |

PT4815, PT3815/SSB |

| PT4315, PT3315/SSB, PT6315 |

PT4415, PT3415/SSB, PT6415 |

PT4615, PT3615/SSB, PT6615, PT3610/SSB |

PT4815, PT3815/SSB |

Without oil seal barrier L2 = tip to tails

With oil seal barrier L2 = tip to oil seal barrier, L3 = oil seal barrier, L4 = oil seal barrier to tails

Order Code Example (with oil seal barrier):

PPB - S - 3 - B - AP - 500mm PT4315 - OSB 6.0 x 60.0 - 1000mm PT4315