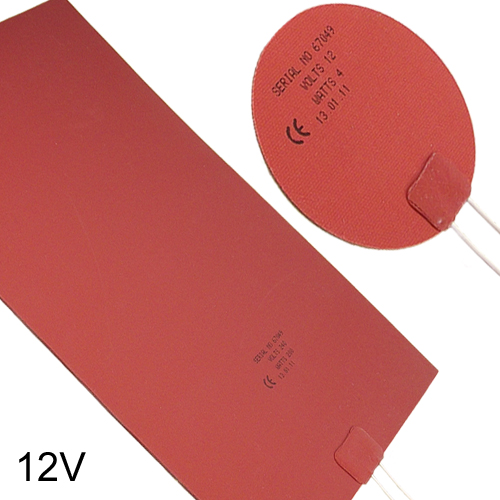

Silicone Rubber Mat Heaters

Product Code: LM

Silicone rubber mat heaters for flat surfaces or awkward shapes. All stocked mats are supplied with 500mm of PTFE flying leads and adhesive backing (rated +180°C continuous). Various sizes, wattages and voltages available.

- Description

- Features

Description

Silicone rubber is ideally suited for the production of heater mats. With its low thermal mass and superb electrical insulation properties it allows high power densities with fast response to temperature control. With silicone’s wide temperature range tolerance of -60°C to 230°C, being thin and lightweight it has a distinct advantage over other forms of heating elements. Where direct, precise and intimate heating is required silicone heaters are the ideal solution.

The stock/standard sensors are of an etched foil construction, with the foil tracks being laminated between two thin layers of silicone to give precise even heating and rapid heat up properties. All stocked mats are supplied with 500mm of PTFE flying leads and adhesive backing (rated +180°C continuous). The mats are semi-flexible.

Where increased flexibility or a bespoke design is required a wire-wound mat offers a good solution. Using evenly spaced resistance wire, laminated between sheets of silicone, they are ideal for prototyping or problem-solving applications.

Bespoke versions which include an integral Pt100 sensor are possible, making them an ideal option for 3D printers.

For applications demanding constant control over the temperature of the heater, an inline thermostat can be supplied which allows instant temperature adjustment.

When manufactured to customer specifications they can be made in an extensive range of shapes and sizes: max width 940mm, max length 3000mm, nominal thickness (with adhesive) 0.8mm…3.0mm.

All stock 240V heaters include a 17mm diameter centre hole

Please note: for high temperature applications alternative materials can be supplied. Contact us for further information or to discuss your custom design requirements.